Babcock’s LGE business has secured a significant contract to supply six cargo handling and fuel gas supply systems for the world’s first Ultra Large Ethane Carriers (ULECs), currently under construction at the Jiangnan Shipyard in China.

These vessels, with a capacity of 150,000m³, are 50% larger than existing Very Large Ethane Carriers (VLECs), marking a new milestone in the transportation of liquefied gas.

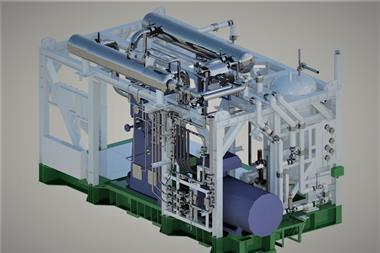

The ships will be equipped with Babcock LGE’s cascade reliquefaction plants to manage Boil Off Gas (BOG), a critical feature for the efficient and safe handling of ethane cargo. The contract reflects the sustained global demand for Babcock LGE’s advanced liquefied gas technologies in a buoyant market.

Neale Campbell, managing director of Babcock’s LGE business, described the project as a pivotal moment for the industry. “The development of these ships is a milestone as we enter the new era of Ultra Large Ethane Carriers. We are proud that our leading-edge technology is integral to these game-changing vessels, with an integrated reliquefaction system and fuel gas supply system providing fuel to the ship’s main engine – helping to support a net-zero future.”

The integrated system will include Babcock LGE’s proprietary SuperCooler and ecoETHN technologies. The company’s SuperCooler enhances plant efficiency by increasing reliquefaction capacity while reducing energy consumption. Meanwhile, ecoETHN™ integrates the reliquefaction plant with the fuel gas supply system, using methane-rich BOG as fuel for the main engine and auxiliary power generators. This approach improves operational efficiency and aligns with sustainability goals.

Babcock LGE division has experienced strong growth, recording over £300 million in orders in the first half of 2024, including 63 contracts from international shipyard customers. This success has been driven by major LNG projects in the Middle East and increasing demand in China.