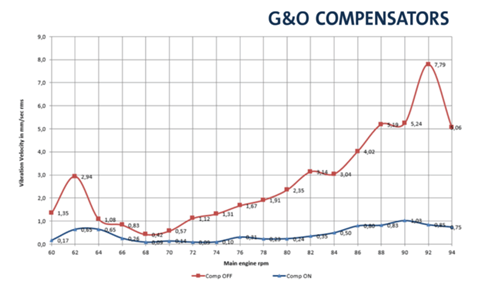

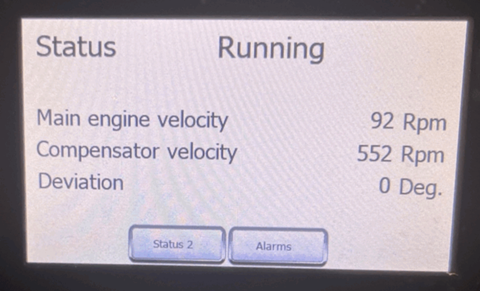

A customer vessel was facing significant vibration issues from the main engine, especially at 92 RPM.

Background

Horizontal vibrations in 6th order exceeded 7 mm/s RMS, pushing both equipment and onboard conditions beyond acceptable thresholds.

High vibration levels like these increase fatigue on structural components and jeopardise the well-being of the crew, especially during longer voyages.

The Customers Challenge

The customer needed a solution that could significantly reduce horizontal engine vibrations without prolonging docking time or compromising engine performance

Solution: Installation of G&O Compensator

G&O Compensators installed one of its high-efficiency horizontal vibration compensators, designed specifically to absorb and counteract complex multi-order vibrations from two-stroke engines.

The installation included:

- Advanced ship vibration analysis before installation

- Implementation of a compensator tuned to the vessel’s operational profile

- On-site fine-tuning and verification by a G&O service engineer

Result: 89.08% Vibration Reduction

After installation, vibration levels fell from over 7 mm/s RMS to well below 1 mm/s RMS in 6th order horizontal motion—a reduction of 89.08%.

This was not just visible in the data, but also in real-life onboard conditions.

“The ship became so calm after the installation that our technician could place a 20 DKK coin on its edge in front of the compensator—and it stayed upright.”

– Morten Kjæmpe, Head of Service & Technical Support, G&O Compensators

Impact

- Major reduction in engine vibration

- Notable reduction in hull stress

- Significant reduction on stress in electrical equipment

- Improved operational stability

- Enhanced onboard comfort for crew

Visual Evidence

|

|

|