The maritime industry is embarking on a transformation, steering away from traditional hydraulic winch mechanisms in favor of advanced electrically operated systems.

The use of variable speed drives (VSDs), also known as variable frequency drives (VFDs) or, simply, drives, paired with high-efficiency electric motors is redefining all kinds of marine winch, including spooling winches, with a focus on energy efficiency, operational precision, and reliability.

The ABB ACS880 industrial drive is setting a new standard in the management of the ropes that are crucial for offshore and mooring vessels around the globe.

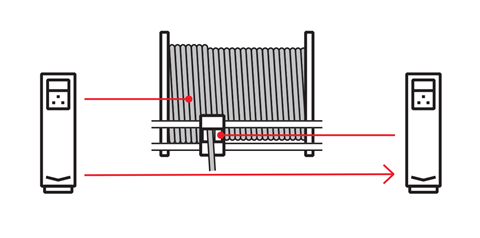

Moving from using mechanical transmission to electrical shaft transmission

Mechanical spooling winches contend with a number of operational challenges. Mechanical and hydraulic power transmission systems face inherent inefficiencies, including wear and tear on the rotating parts that require synchronisation. The physical bulk and complex nature of their mechanical transmission includes wheels, gears and chains that makes them difficult to maintain and keep in sync.

ABB’s solution replaces the mechanical power shaft transmission with an integrated electronic synchro shaft functionality, similar to an electronic gear rather than mechanical gearing. This is made possible via the software built inside the ACS880 industrial drive that controls the motors of the main winch and spooler device. This approach allows for the electrical spooling device or motor to remain mechanically independent from the main winch, while maintaining precise synchronisation through the spooling software embedded in the drive. This ensures streamlined and safer management of ropes on offshore and mooring vessels, due to the integrated coordination between the main winch and spooler device.

Process control and energy efficiency

The traditional mechanical transmission spooling devices offer raw strength but lack the precision needed to adequately control the rope’s tension and position. This limitation and less controlled operation can result in ‘bird nesting,’ where ropes tangle and overlap, potentially damaging both the ropes and the winch and putting the safety of the equipment and crew at risk, especially with deep sea winches that has a long rope on the drum in multilayers.

In addition, these systems, which involve chains, belts, and wheels, are large and cumbersome, requiring a lot of space. The wear and tear from their use can lead to uncontrolled spooling operations. These systems also present challenges in extreme weather conditions, such as arctic environments.

Transitioning to electric winches powered by motors and drives has the potential to revolutionise maritime deck operations, and comes with a huge range of benefits. The precise control afforded by drives directly mitigates the risk of improper spooling. The drive’s ability to control the speed of the motor allows for careful management of winch speed and torque, ensuring smooth operation and protecting the ropes from undue stress and wear.

Electric winch systems react quickly and precisely to operational commands, providing a big improvement on the slower response times that traditional mechanical transmission systems have.

By using drives, electric winch systems can match energy consumption to actual demands. This not only prevents excessive energy use, but also promotes long-term operational cost savings and a marked reduction in the associated emissions.

Tight side by side, and layer by layer for multilayer turn system on the drum

ABB has introduced a ready-made, innovative solution to address the challenges posed by traditional marine winch systems. With an expanded offering for the marine winch market, ABB’s marine drive family, the ACS880, includes a dedicated a new application software designed to enhance spooling and rope guiding functions.

The key feature of this solution is a ready-made AC drive application tailored for synchronised operations between the main winch drive and the spooler device. It facilitates direction changes effortlessly, filling one layer completely before advancing to the next, all while maintaining the desired fleet angle – this is essential for orderly and safe spooling.

The drive-based spooling control software provides a user-friendly interface, ready for configuration via a PC tool that simplifies parameter adjustments. Its diverse features and functionalities meet the varying needs of marine winch operations, including:

- Manual and automatic modes: In manual mode, the operator manually controls the movement of the spooler to the left and right for servicing and inspection of the system. In automatic mode, the system automatically directs the spooler left and right in synchronisation with the rotation of the main drum.

- Direction change logic: In automatic mode, the system can seamlessly switch the spooler’s direction from left to right using discrete input sensors, actual position feedback from sensors.

- End-limit logic for both left and right sides, configurable via discrete input sensors or actual position feedback, to prevent the rope from overrunning the spooling area. This can be used in manual mode and automatic mode. If an end-limit switch sensor fails, a backup torque limit can be used to detect when the system is operating outside of its range and approaching a mechanical endpoint.

- Fleet angle support, which maintains a specified angle during spooling to ensure ropes lay tightly side by side without gaps or overlaps. This can be done with proximity sensors to define a permitted operating area.

- Options for referencing the main drum or the line reference with various inputs, such as encoders, PLC function blocks, analog inputs, or through ABB’s high-speed drive-to-drive communication between ACS880 drives.

- Scalable parameters to match the gearing ratio between the main drum and the spooler device, allowing for optimised coordination and control.

- Support configurations for tracking or non-tracking gear mechanisms, accommodating either unidirectional or bidirectional gear arrangements.

Thanks to this integrated software and the versatile functionality of the ACS880 marine drive, operators can expect significantly improved spooling accuracy and efficiency. The system’s ability to adapt to different operational modes, coupled with the support for extreme temperatures, translates to more reliable and safer marine winch operations, effectively mitigating common issues such as tangling and bird nesting.

Digital advantages

The collaboration between dedicated drive software and PLCs is key to delivering advanced winch operations. This level of automation allows for sophisticated control strategies and real-time adjustments, ensuring operations are executed with accuracy and coordination. For example, the ACS880 drive software can regulate the layering of rope on the drum to prevent tangles and overlaps, while drives or PLCs can synchronise multiple winch drums for balanced load distribution, which is vital for complex lifting operations.

The drive software also facilitates adaptive programming, which helps maritime workers to customise operations to accommodate the unique demands of the vessel and the sea conditions. Through integrated diagnostics and monitoring, PLCs can also provide critical operational data as feedback, including load tension, motor speed, system temperature, and electrical current values, which allows for the analysis of the winch’s performance and condition in real-time.

This information is essential for implementing predictive maintenance strategies, as it enables the anticipation of potential maintenance needs based on actual usage and wear patterns, rather than on a predetermined schedule. This proactive approach better maintains the winch system’s reliability, cost-effectiveness, and lifespan.

Smarter setup with same technology for main winch and the spooling device

Maritime operators also benefit from the user-friendly nature of electric winches with drives. The common hardware and software platforms standardise setup procedures, making troubleshooting and maintenance much more straightforward. Instead of having different parts and unique software for each type of winch, manufacturers can design a range of winches that use the same core components such as motors, drives, control units, and the software interfaces that operate them. This means that operators can use similar procedures to install, program, and repair multiple winch systems across their fleet.

This reduces the need for specialised setup and training, resulting in reduced engineering time and overall reductions in operational costs. Electric winching systems with fewer mechanical components also have fewer potential failure points, leading to lower maintenance requirements and better reliability. The added convenience of removable memory units for software simplifies the management of configurations and updates, further streamlining the setup and maintenance processes.

Charting a new course

The integration of motor-drive systems and PLCs in marine spooling winch operations is ushering in a significant advance in maritime technology, enhancing precision, efficiency, and adaptability.

Through optimised energy consumption, refined operational control, and vastly improved safety, electric winch systems are now an asset for the modern maritime industry. As vessels continue to traverse the seas, the adoption of these advanced electric winches with ABB ACS880 drives signals a commitment to innovation, sustainability, and progress.