An inquiry from our Turkish partner, Novar, initiated a close development process with RMK Marine Shipyard regarding the delivery of a customdesigned ejector system for tank emptying.

An inquiry from our Turkish partner, Novar, initiated a close development process with RMK Marine Shipyard regarding the delivery of a customdesigned ejector system for tank emptying.

The project includes technical clarifications, practical tests, and a potential main delivery of a total of 32 stainlesssteel ejectors.

Inquiry and Requirements Definition

RMK Marine, one of Turkey’s leading shipyards with activities spanning commercial vessels as well as specialized maritime projects, submitted, together with Novar, a request for an ejector system to be used in their tankemptying applications.

Their requirements were clear: high operational reliability, stable performance, and a solution that could be seamlessly integrated into the shipyard’s existing systems.

Technical Coordination and Specification

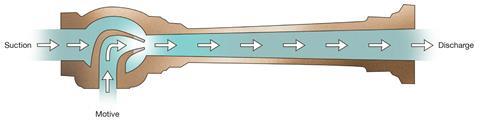

Based on the initial dialogue, a structured technical collaboration was established between the parties. Through a series of reviews and alignment meetings, a detailed specification was developed addressing capacity, material selection, and installation conditions.

This process ensured that the solution matches RMK Marine’s operational requirements while building on our experience with ejector systems for demanding maritime installations.

Prototype Delivered for Testing

To validate functionality and performance in practice, a prototype ejector has been sent to Turkey for testing at RMK Marine.

The test phase is an important step to confirm that the system design meets the operational prerequisites and can form the basis for the planned main delivery.

Potential Delivery: 32 StainlessSteel Ejectors

If the test results meet expectations, the next phase will include the delivery of two complete systems, each consisting of 16 ejectors manufactured in stainless steel. The choice of stainless steel for the final ejectors is essential for both reliability and long service life.

Stainless steel provides significantly higher resistance than traditional materials. It reduces the risk of corrosion, minimizes maintenance needs, and contributes to more stable longterm operation.

Additionally, the material’s mechanical strength ensures a high and consistent performance even under fluctuating load conditions, making it particularly well suited for tankemptying systems in continuous operation.

The project represents one of the larger configured ejector deliveries to the Turkish market and will strengthen the technical cooperation between all three parties.

Project Partners

Novar is an established technical partner in Turkey with strong local presence and extensive experience supporting maritime and industrial projects. Their role as liaison and project coordinator has been central throughout the process.

RMK Marine is one of the region’s most advanced shipyards, known for quality, engineering expertise, and projects within advanced maritime applications.

“We look forward to further expanding our collaboration in the future and continuing to deliver solutions that support stable and efficient operations for our partners.”

IRON Pump CEO Anders Frimodt-Møller